To navigate the complexities of today’s business landscape and ensure long-term success, organizations must adopt a structured approach to enhance manufacturing cost efficiency and bolster cash flow. By doing so, they can uncover untapped value streams and drive sustainable improvements in performance.

We are convinced that an Operations Optimization approach focusing on manufacturing cost and working capital optimization with strong employee engagement is the best option to improve. By empowering employees and optimizing operational processes, businesses can not only overcome existing challenges but also position themselves for future growth and resilience.

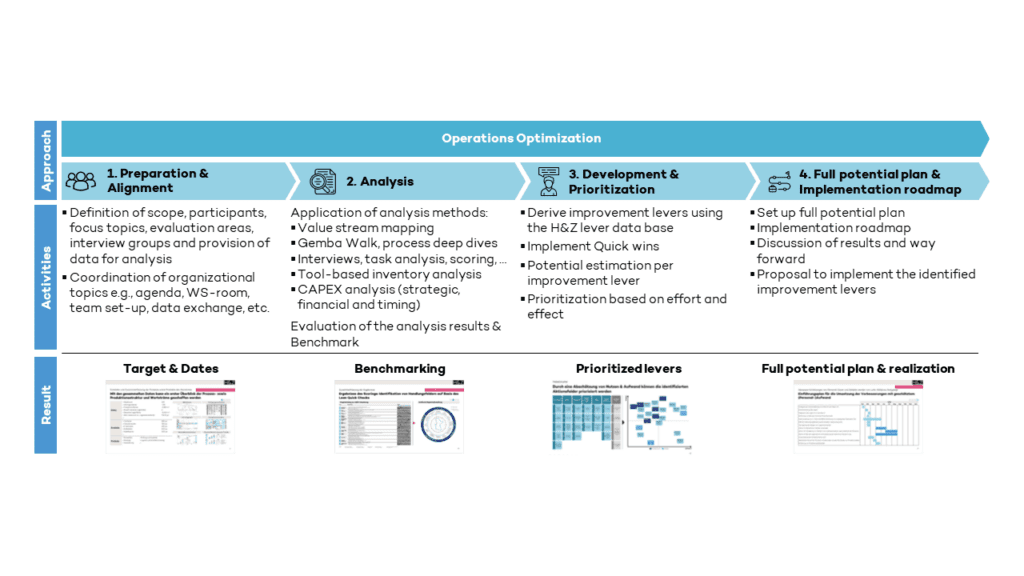

A Strategic Four-Step Approach

H&Z’s Operations Optimization is structured around a four-step process, meticulously crafted to ensure that each stage builds upon the last to maximize effectiveness.

The initial step, Preparation & Alignment, sets the groundwork by defining the scope, participants, focus topics, and the critical data necessary for subsequent analysis. This stage is crucial as it aligns all organizational elements and prepares the team for a smooth transformation journey.

Following preparation, the Analysis phase employs sophisticated tools like Value Stream Mapping and Gemba Walks, alongside deep-dive interviews and strategic benchmarking. These methodologies are not just about identifying inefficiencies but understanding the underlying causes that may be hindering operational performance. This phase aims to highlight actionable insights that pave the way for targeted improvements.

At the heart of the framework is the Development & Prioritization phase, where H&Z leverages its expansive extensive lever database, containing around 1000 proven operational levers. This resource is instrumental in deriving tailored improvement strategies that are prioritized based on their potential impact and ease of implementation. This methodical approach ensures that resources are allocated efficiently, focusing on changes that offer the most significant benefits.

The culmination of this process is the Full Potential Plan & Implementation Roadmap. This final phase delivers a comprehensive plan that outlines specific actions, target dates, and expected outcomes. It serves as a blueprint for sustained operational excellence and ensures that the implemented changes are embedded within the company’s culture, guaranteeing long-term benefits.

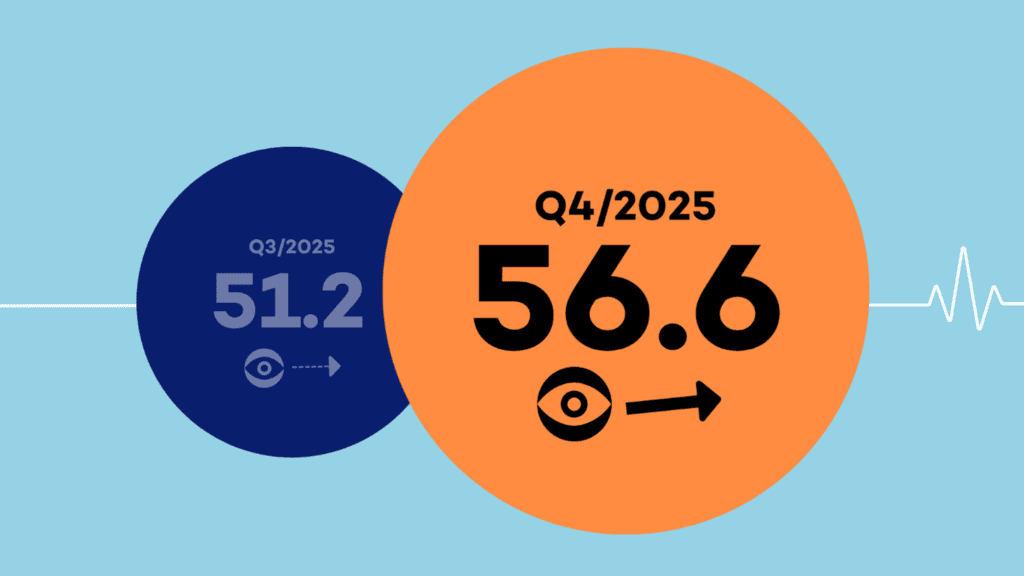

Quantifiable Benefits and Real-World Application

The Operations Optimization framework is not just a theoretical model but a solution born out of H&Z’s extensive consulting experience across various industries. Businesses implementing this strategy can expect to see substantial improvements, including a 15-30% reduction in working capital and a 15-20% decrease in manufacturing and operational costs. These savings are vital in today’s economic landscape, where efficiency and agility are paramount to maintaining a competitive edge.

Get in Contact with our expert

Sandra Stoll

With 20+ years in the sector, Sandra leads H&Z’s Industrial Goods Practice and is passionate about driving measurable performance improvement. Recognised as a trusted advisor, she specialises in performance solutions for industrial goods companies.