H&Z’s Operations Optimization is structured around a four-step approach, meticulously crafted to ensure each stage builds upon the last to maximize effectiveness. Initially the preparation phase lays the foundation by defining the scope, participants, focus topics, and essential data. In a second step the Analysis phase utilizes well proven tools such as Value Stream Mapping, Gemba Walks and Process deep dives at the point of use to identify inefficiencies and their causes. This phase focuses on uncovering actionable potential that leads to targeted and quantified productivity and efficiency improvements.

H&Z’s ‘Lever Database’ – A Comprehensive Toolbox to Swiftly Identify Cost Reduction & Productivity Improvement Levers

In a third step the core of H&Z’s operations optimization framework comes into play: the Concept Development phase. At this point we weigh, combine and sequence single actions and improvement levers, to create a comprehensive concept that is tailored to the conditions of the respective project and thus to the requirements of our client. From our experience, this is crucial for the actual implementation of productivity-enhancing measures, as it is the only way to achieve sufficient acceptance among management and staff.

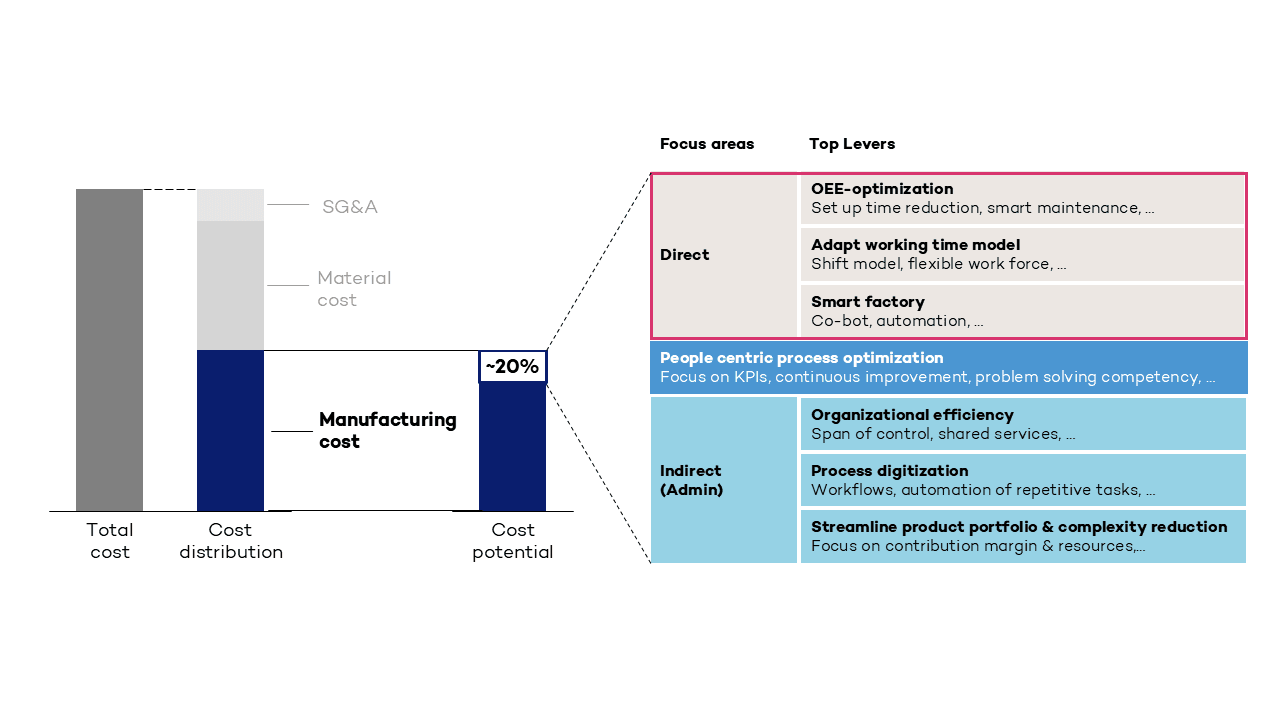

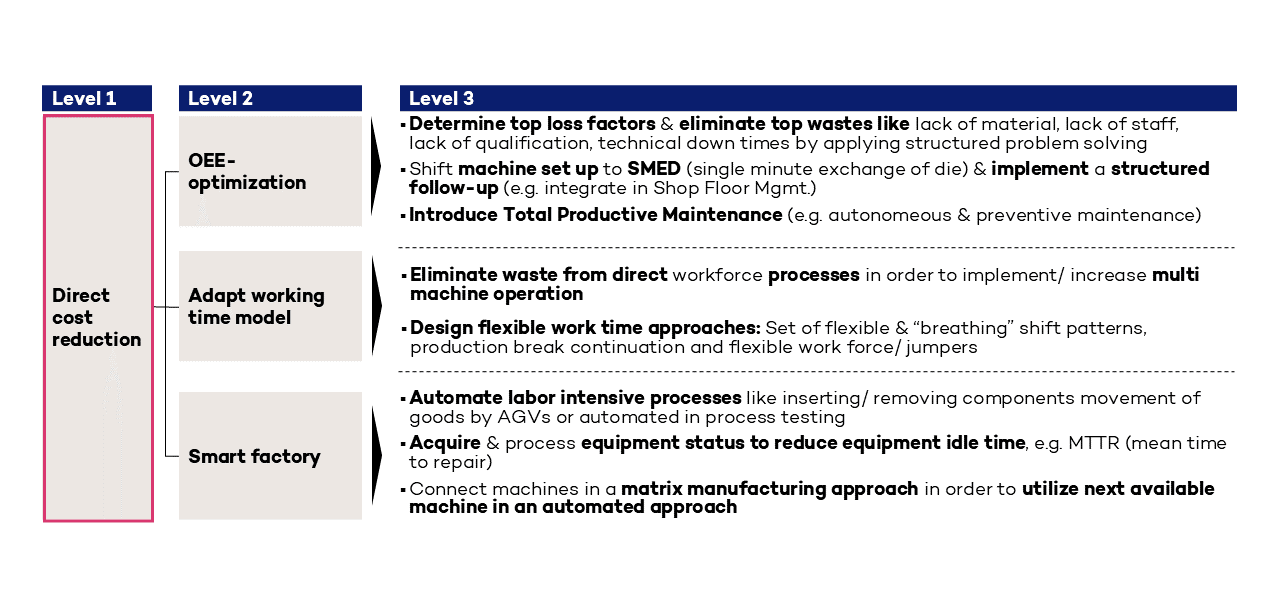

Here we utilize the H&Z ’lever database’ with over 1000 operational levers, most of them in the category “Direct cost reduction”. It is our knowledge base which, to derive and prioritize tailored efficiency measures and improvement strategies. This strategic prioritization focuses on the potential impact and implementation ease, ensuring efficient resource allocation and maximum benefits. By doing this, we lay the groundwork from the start to ensure maximum implementation efficiency with optimal resource utilization in the 4th phase, ‘Potential Calculation & Implementation Roadmap’.

Here we utilize the H&Z ’lever database’ with over 1000 operational levers, most of them in the category “Direct cost reduction”. It is our knowledge base which, to derive and prioritize tailored efficiency measures and improvement strategies. This strategic prioritization focuses on the potential impact and implementation ease, ensuring efficient resource allocation and maximum benefits. By doing this, we lay the groundwork from the start to ensure maximum implementation efficiency with optimal resource utilization in the 4th phase, ‘Potential Calculation & Implementation Roadmap’.

Quantified Benefits & Practical Applicability

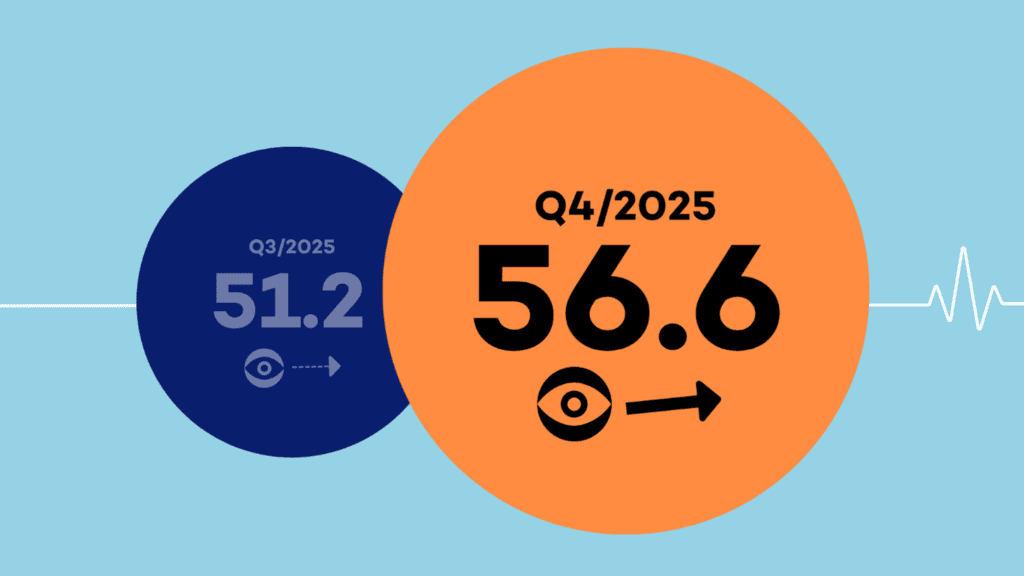

The Operations Optimization Framework is grounded in H&Z’s extensive consulting experience across various industries, like Automotive, engineered products, process industry to name just some examples. In joint projects, our clients regularly achieve cost reduction potentials through the H&Z approach, with efficiency improvements in production and support areas of up to 20%. Productivity improvements of this magnitude are a crucial competitive advantage in the current tense economic situation.

Get in Contact with our expert

Sandra Stoll

With 20+ years in the sector, Sandra leads H&Z’s Industrial Goods Practice and is passionate about driving measurable performance improvement. Recognised as a trusted advisor, she specialises in performance solutions for industrial goods companies.

Dr. Markus Contzen

For more than 20 years, Markus has been working for Private Equity customers along the complete investment lifecycle – before, during, and beyond the deal – driving value potential.