A Bold Leap in Battery Safety: GB38031-2025

China’s Ministry of Industry and Information Technology (MIIT) recently issued a groundbreaking safety regulation – GB38031-2025 – that marks a global first in EV battery mandates. Effective July 1, 2026 for new EV type approvals, and July 1, 2027 for existing vehicles, this regulation enforces unprecedented standards in thermal safety, structural integrity, and longevity of batteries.

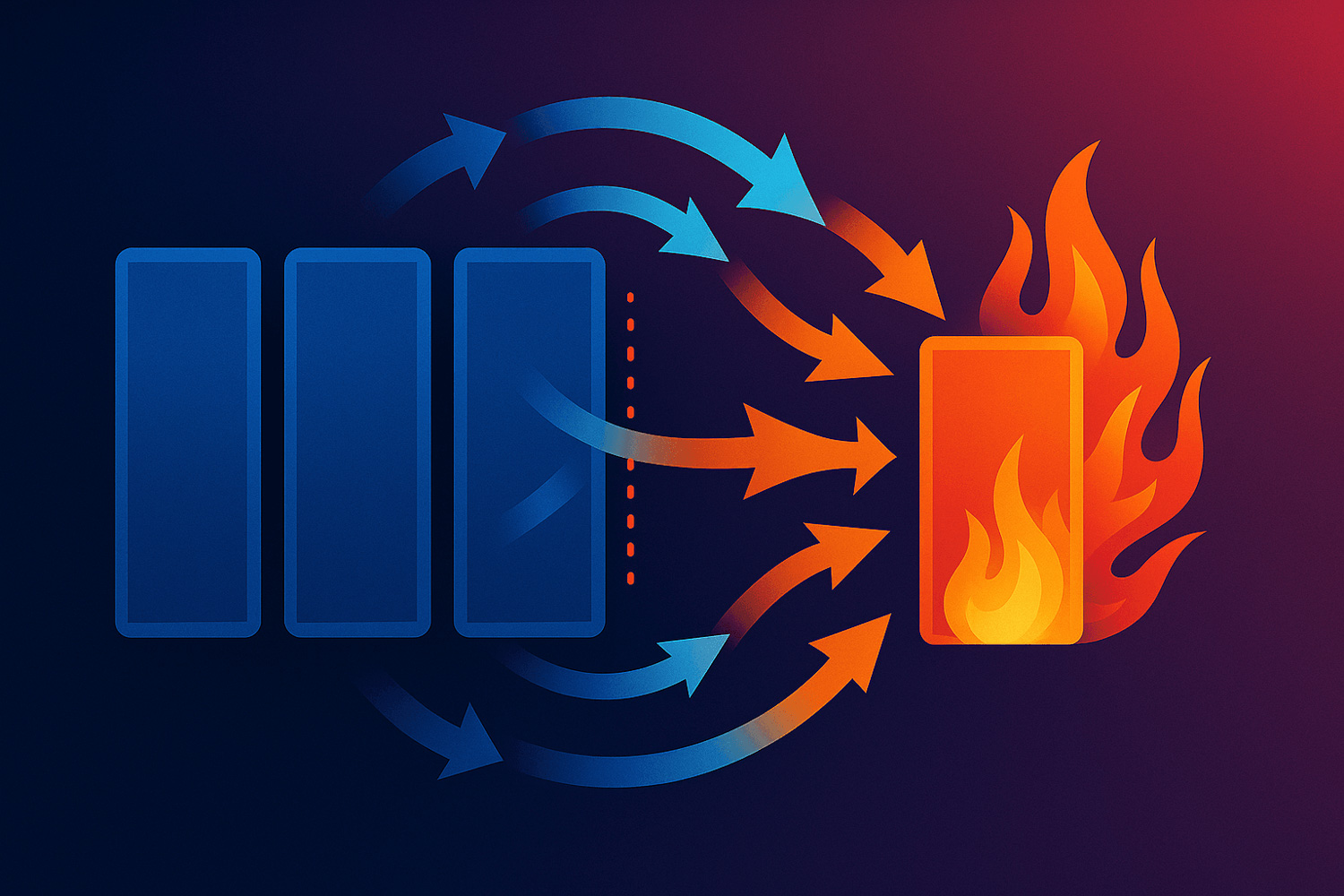

For decades, EVs have battled one common villain: thermal runaway. This chain reaction, triggered by internal failures, leads to heat surges, smoke, and sometimes catastrophic explosions. GB38031-2025 doesn’t just aim to delay disaster – it demands it be altogether prevented.

From „Evacuation Time“ to „Absolute Safety“

The new regulation enforces a revolutionary principle: no fire, no explosion—even if a thermal runaway event is initiated. This is a monumental shift from previous standards, which only required early warning systems five minutes before a possible ignition.

The regulation’s cornerstone test—the Thermal Propagation (TP) test—forces battery systems to demonstrate the ability to contain a runaway event for at least two hours without any fire or explosion. Moreover, no visible smoke must enter the vehicle cabin during or after the incident.

Key Requirements in Thermal Propagation Testing:

- State of Charge (SOC) at ≥95%

- Temperature at 22 ± 5°C

- Smoke must not enter the cabin 5 minutes before or after thermal event alarms

- The battery must remain below 60°C at all monitoring points during the 2-hour window following thermal runaway

This means EV manufacturers now face a binary choice: redesign their battery systems or risk being banned from the Chinese market.

Fast Charging Meets its Reckoning

EV buyers love fast charging, but it’s a silent culprit behind battery degradation. The new Fast-Charging Cycle Safety Test in GB38031-2025 takes direct aim at this risk.

The Challenge

Fast charging – especially rapid 20–80% cycles—can cause lithium plating and accelerate wear. This leads to heightened risk of thermal events.

The Regulation’s Response:

- Batteries must undergo 300 fast-charge cycles (20% to 80% SOC within 15 minutes).

- After this, batteries are subjected to external short circuit testing using a 5 mΩ resistor for 10 minutes.

- Pass/Fail Criteria: No fire. No explosion.

Manufacturers now have to prove that even after aging, their batteries will hold up in the face of extreme stress—no exceptions.

Bottom Impact: Ground Zero for Safety

The Bottom Impact Test is another game-changer. As EVs become sleeker and low-riding, they are increasingly exposed to road debris and underbody impacts.

Test Details:

- 30 mm diameter impactor, 150 Joules of energy

- SOC ≥ 95% for externally chargeable batteries

- Three repeated impacts on the battery pack

Safety Musts:

- No fire

- No explosion

- No structural rupture or leakage

- Insulation resistance must remain intact

This puts significant pressure on OEMs to rethink pack placement, protective shielding, and even vehicle ground clearance.

Economic and Strategic Earthquake for OEMs

Complying with GB38031-2025 is not just an engineering hurdle—it’s a business dilemma.

Here’s why:

- Legacy battery designs might not comply, forcing massive re-homologation efforts.

- Development and testing require non-budgeted investment, affecting margins.

- Higher safety specs likely increase battery cost, threatening competitiveness.

Strategic choices include:

- Withdrawing from China (writing off current platforms)

- Fast-tracking next-gen platforms

- Costly redesign of existing products

For automakers, the question is no longer if they need to adapt, but how fast they can do so without bleeding market share or budget.

The Global Domino Effect

This regulation is China’s gift—and challenge—to the world. With whispers of it being proposed for global harmonization under UN ECE R100 Revision 5 (2027), GB38031-2025 is poised to become a global benchmark.

Industry insiders already predict ripple effects in:

- Europe: Automakers are pushing to future-proof their platforms

- North America: Startups and legacy brands alike must factor these standards into battery development

- Gigafactory planning: Global cell manufacturers are reevaluating chemistries and production lines

China’s dominance in LFP (Lithium Iron Phosphate) chemistry, which aligns better with these fire-safety mandates, may grow even stronger.

H&Z: Navigating Compliance

Amid this upheaval, H&Z is helping OEMs make sense of the chaos.

What’s Offered:

- 6-week comprehensive assessment of technical and financial feasibility

- Deep dives into:

- Vehicle exposure and platform mapping

- Business case impact of compliance options

- Product cost and competitiveness analysis

- Portfolio strategy and roadmap revisions

A dedicated PMO and engineering taskforce ensures implementation stays on track – whether that’s a pack redesign, software-based safety boost, or new battery chemistry selection.

What Happens Next?

The countdown has begun. By mid-2026, automakers must decide how they’ll meet GB38031-2025’s sky-high bar.

Expect the following in 2025:

- Redesign races among legacy automakers to secure re-homologation

- Startups marketing “compliant by design” batteries

- Funding rounds for thermal management innovators

- Global regulatory lobbying to either adopt or resist the new standards

One thing is clear: GB38031-2025 is not just a safety regulation. It is a techno-economic gauntlet that demands new engineering paradigms, reshapes go-to-market timelines, and may determine the next generation of EV leaders.

Final Thoughts

GB38031-2025 brings clarity, if also chaos. It signals a maturing EV industry where battery safety is not negotiable. The rule doesn’t just punish failure – it forces a reinvention of how batteries are made, tested, and trusted.

OEMs, suppliers, and even investors now face a singular truth: if your batteries can’t survive thermal propagation, your business might not survive the market.