Automotive Industry

The automotive industry is at the forefront of adopting circular economy principles, yet it still holds considerable potential for further growth. Key trends driving this transformation include vehicle electrification, the development of autonomous driving technologies, enhanced connectivity, and innovative mobility services such as carpooling and shared mobility. Sustainability initiatives, including decarbonization, sustainable production, remanufacturing, recycling, and energy efficiency, are also paramount.

Organizations like the European Association of Automotive Suppliers (CLEPA), the European Automobile Manufacturers Association (ACEA), and other global industry associations play a crucial role in promoting circular practices within the sector. The industry faces the challenge of integrating new technologies while also meeting regulatory pressures on environmental protection and waste reduction. External factors, including regulatory pressure, macroeconomic conditions, consumer demand for sustainable products, and potential cost savings, drive the shift towards a circular economy, with OEMs pushing these initiatives onto suppliers.

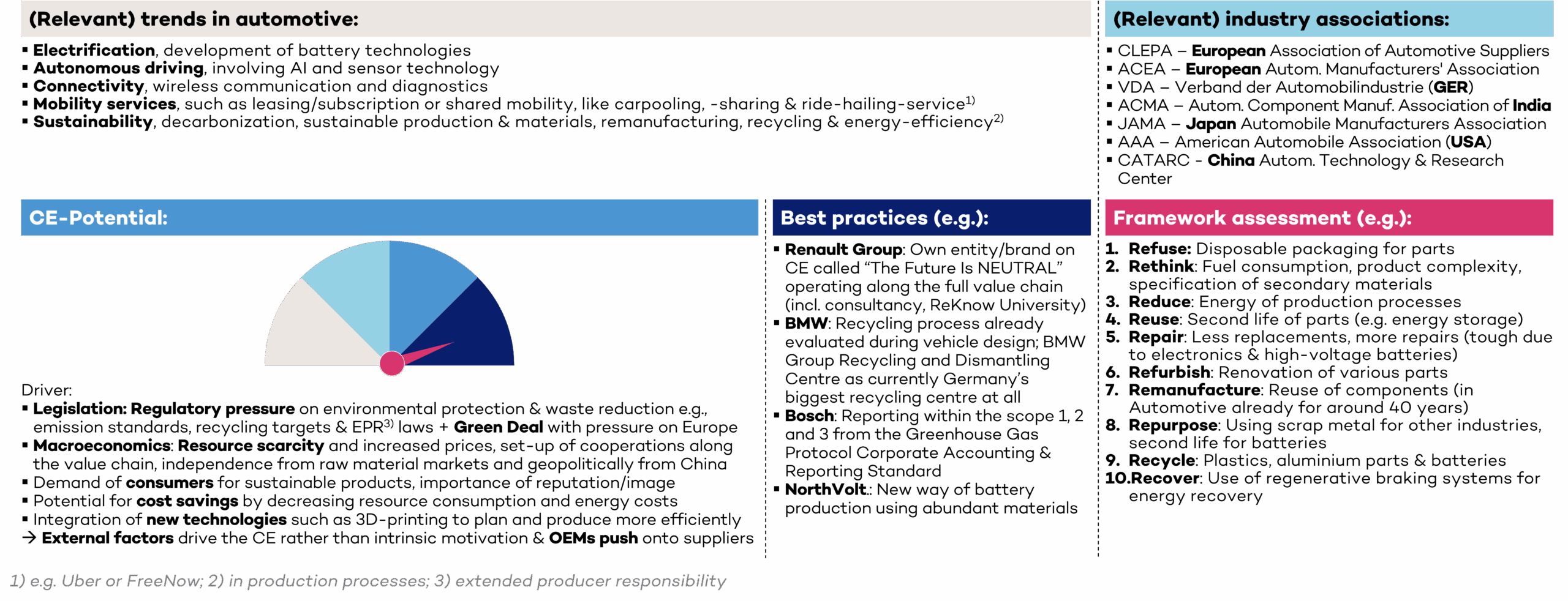

Rail Industry

The rail industry is already implementing advanced circular economy practices. Key trends such as the expansion of network electrification and hydrogen fuel options, like Alstom’s Coradia iLint, are at the forefront. Operational efficiency improvements, such as Wabtec’s Trip Optimizer to reduce diesel fuel consumption, and sustainable value chain integration, exemplified by Deutsche Bahn’s strategy, are shaping this sector.

Other notable practices include Network Rail’s initiatives for recycling rail materials and promoting renewable energy sources, Alstom’s eco-design process, and NS’s circular entrepreneurship program optimizing materials use.

The rail industry’s foundations, such as the long lifespan of infrastructure, are compatible with circular economy principles. Positioning as a sustainable transportation alternative, driven by cross-company initiatives like Railsponsible, emphasizes the importance of circularity. While recycling and reuse of materials are well-established, there is still room for improvement through more unified global standards and practices.

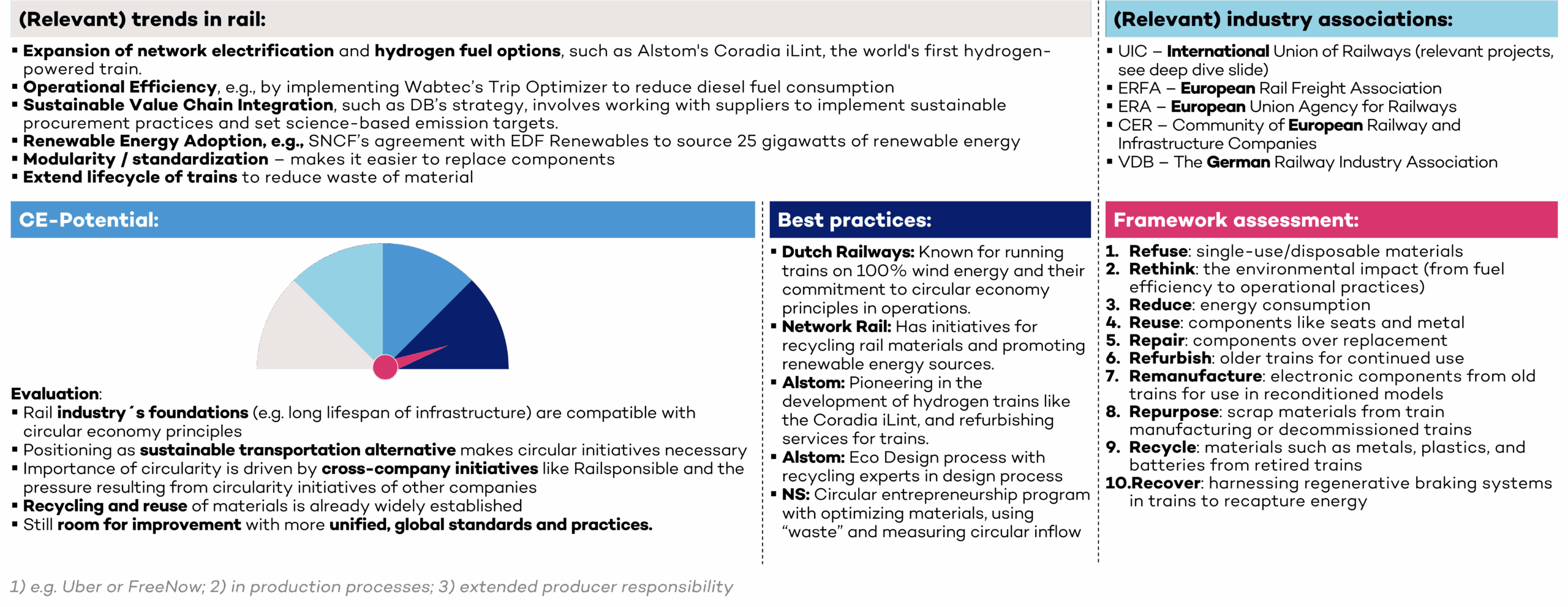

Aviation Industry

The aviation sector is making strides towards adopting circular economy principles, with both original equipment manufacturers (OEMs) and operators (airlines and airports) driving innovations and sustainability efforts.

OEM (Original Equipment Manufacturers)

Original equipment manufacturers (OEMs) in the aviation sector are making significant advances in embracing circular economy principles. Key trends include the development of hydrogen-powered airplanes, autonomous flights leveraging AI and sensor technology, and advanced air mobility innovations such as electric vertical takeoff and landing (eVTOL) vehicles. While OEMs are driving innovation, realizing the full potential of circular economy practices is constrained by technical, regulatory, and economic barriers. These challenges underscore the need for continuous efforts to enhance sustainability in the aviation industry.

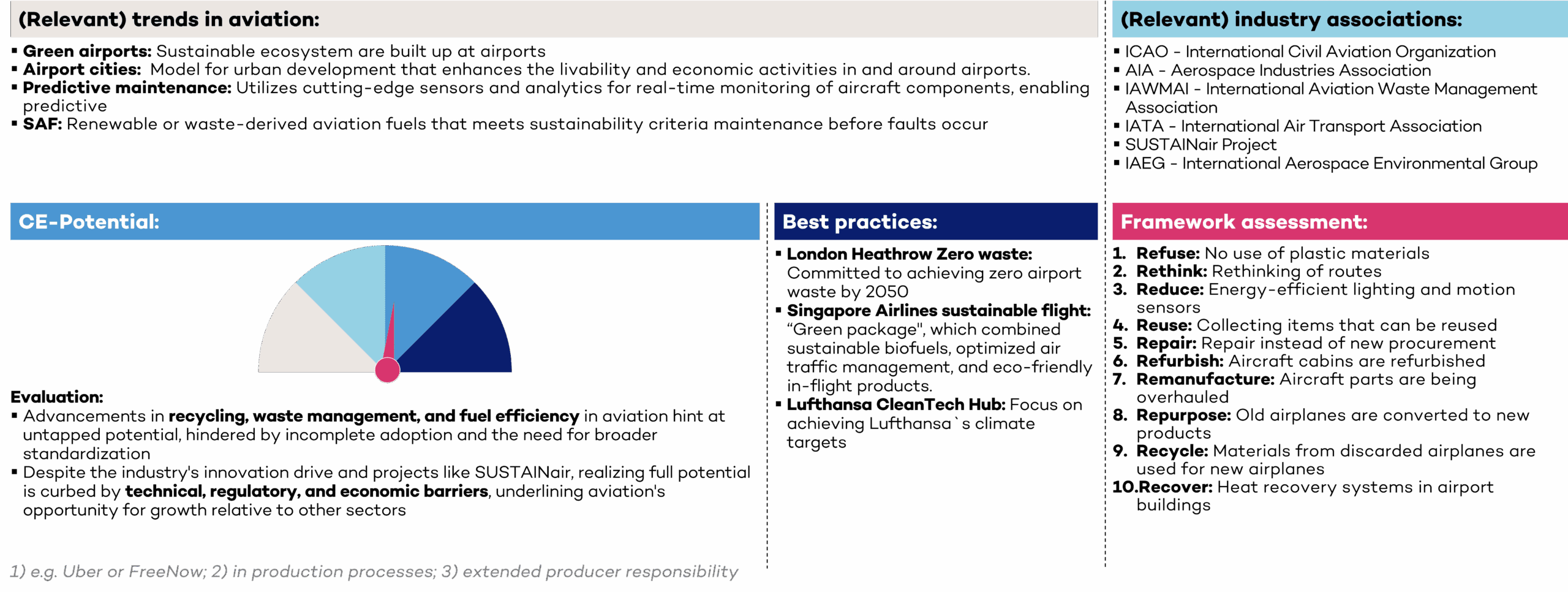

Operations (Airlines & Airports)

In aviation operations, significant progress is being made in adopting circular economy principles. Key trends include the development of green airports, which create sustainable ecosystems, and airport cities that enhance livability and economic activities. Predictive maintenance technologies utilize cutting-edge sensors and analytics for real-time monitoring of aircraft components, enabling preemptive maintenance.

Despite advancements in recycling, waste management, and fuel efficiency, there is further potential e.g. with broader standardization. Projects like SUSTAINair highlight the industry’s innovation drive.

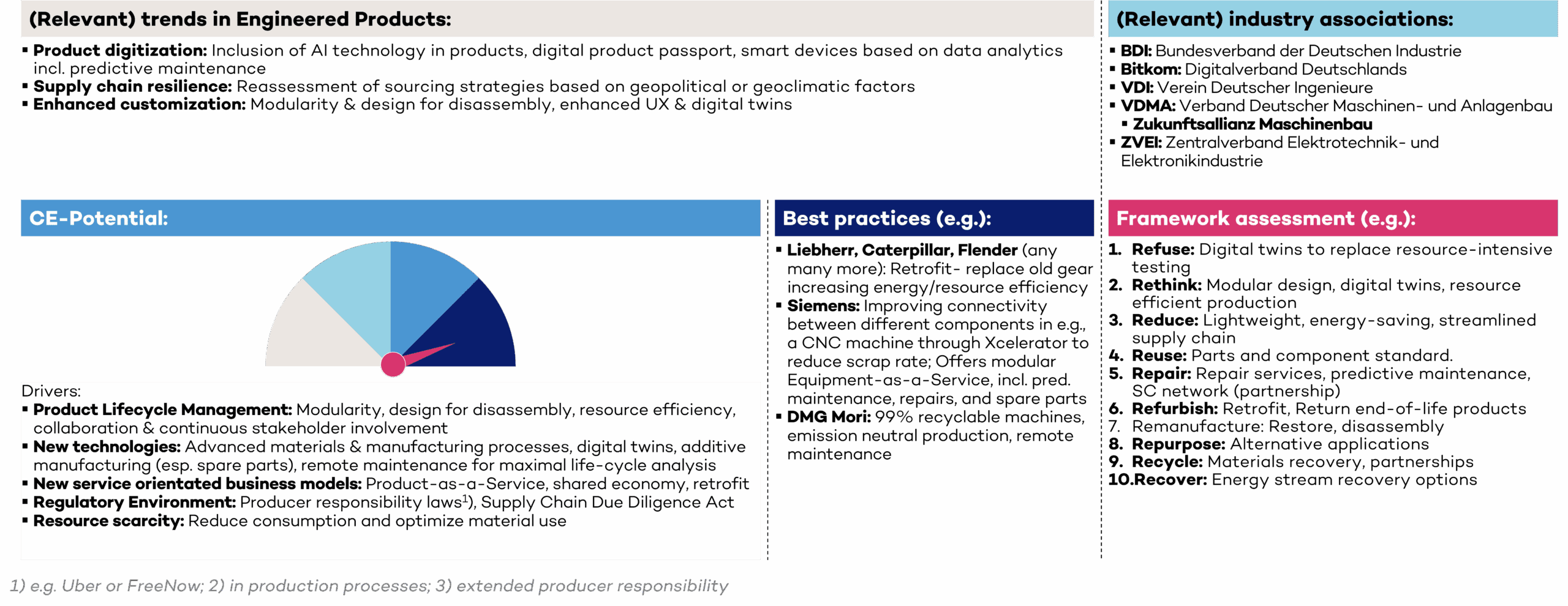

Engineered Products Industry

The engineered products sector holds considerable potential to advance the circular economy, with a high growth potential. Key areas of focus include product lifecycle management, the adoption of new technologies, and the resilience of supply chains. Trends such as product digitization, supply chain resilience, and enhanced customization are shaping the sector.

Leading companies like Liebherr, Caterpillar, Flender, and Siemens are implementing innovative solutions that promote circular production methods. Best practices include retrofitting old gear to increase energy and resource efficiency, improving connectivity between different components, and offering modular equipment-as-a-service models.

The framework assessment highlights the importance of digital twins, modular design, lightweight and energy-saving approaches, repair services, and various methods to repurpose and recycle materials.

Summary

The journey towards a circular economy is gaining momentum across various industrial sectors, each demonstrating unique strengths and facing distinct challenges. Despite the varying degrees of progress, all sectors share a common goal: to optimize resource use, reduce waste, and enhance sustainability. By adopting circular economy principles, these industries not only contribute to environmental preservation but also drive economic growth and innovation. Continued collaboration, regulatory support, and technological advancements will be essential to fully realize the benefits of a circular economy, paving the way for a circular future.