Optimizing S&OP Efficiency

Client Challenge

The client’s organization had developed over time with complex, historically rooted structures and processes that lacked a cohesive, strategic design. Integration of acquired companies remained incomplete, leading to overlapping responsibilities within Sales and Operations Planning (S&OP) and resulting in inefficiencies. This partial integration also created misalignment, with both the integrated teams and the existing organization attributing accountability issues to one another when challenges emerged.

Furthermore, different segments of the organization operated with distinct processes, approaches, and systems, each relying on separate tools and methods. Key functions intersecting with the S&OP process were insufficiently involved in decision-making, causing coordination challenges and gaps in accountability.

While capacity constraints due to high demand were a given, the organization’s current setup hindered its ability to navigate these challenges effectively. Furthermore, there was a large management pressure, as penalties for non-timely deliveries can range in the millions. This lack of cohesion limited the company’s responsiveness to market needs, impeding its ability to fulfil customer demand reliably and meet delivery expectations.

H&Z Approach

The manufacturer partnered with H&Z to develop a comprehensive and tailored solution aimed at significantly improving the Sales and Operations Planning (S&OP) process. This collaboration began with a detailed maturity assessment of the existing S&OP framework, including its processes, tools, and organizational setup. Through interviews with key stakeholders, critical pain points and inefficiencies were identified, providing a clear foundation for improvement.

To design an optimized “to-be” process, H&Z facilitated interactive stakeholder workshops. These sessions focused on crucial elements such as governance structures, role definitions, responsibilities, planning horizons, and the level of data granularity needed for effective decision-making. The outcome was a globally streamlined and cohesive process and related governance ready for implementation.

To ensure the new process could be effectively supported, the H&Z supported the manufacturer in defining an organizational structure better suited to the demands of the enhanced S&OP process. This new structure effectively reduces interfaces with a global set-up addressing the existing split responsibilities.

To properly support the new process and the new organization, H&Z together with H& (H&Zs digital consultancy daughter) led the software selection process for an advanced S&OP tool, to ensure the chosen platform could seamlessly integrate data and streamline operations. This ensured that the tools were aligned with the organization’s strategic goals and provided a real benefit to the users.

Supporting this transformation, a detailed six-month implementation roadmap was created to ensure the new framework could be rolled out smoothly and efficiently.

Results

- S&OP process harmonized and standardized, with governance, roles, and responsibilities clearly defined

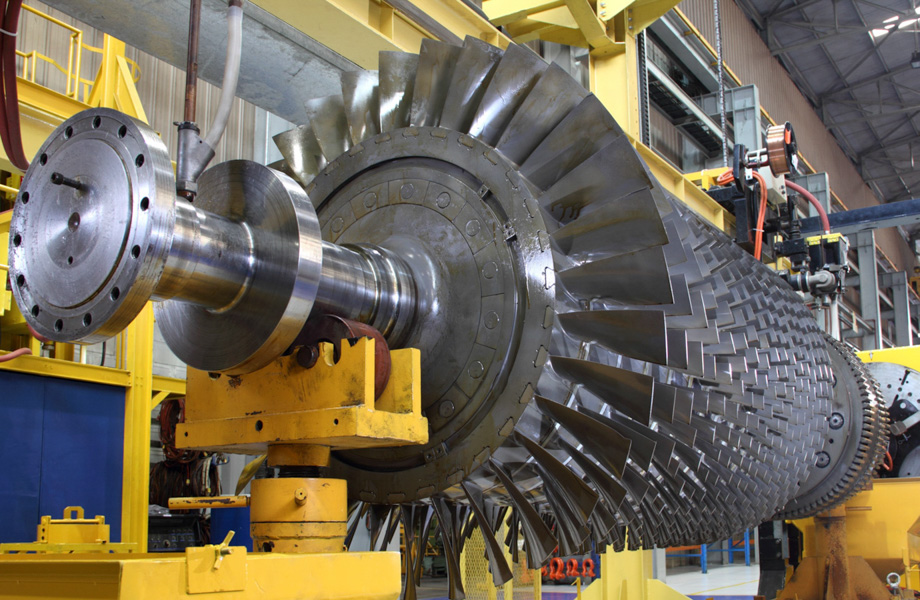

- Organizational structure redesigned, including the establishment of a new department, now enabling more agile and effective responses to the evolving gas turbine market

- Central planning unit implemented to oversee a unified S&OP process across locations

- S&OP reporting and planning tool selected and recommended

- Six-month implementation roadmap finalized

- Stakeholder alignment through close collaboration with the client, ensuring solution fit

With these improvements, the client is now able to operate more efficiently and can now better handle the recent demand spike and supply constraint they initially faced.