Strengthening the Supply Chain through Dual Sourcing and Cost Reduction

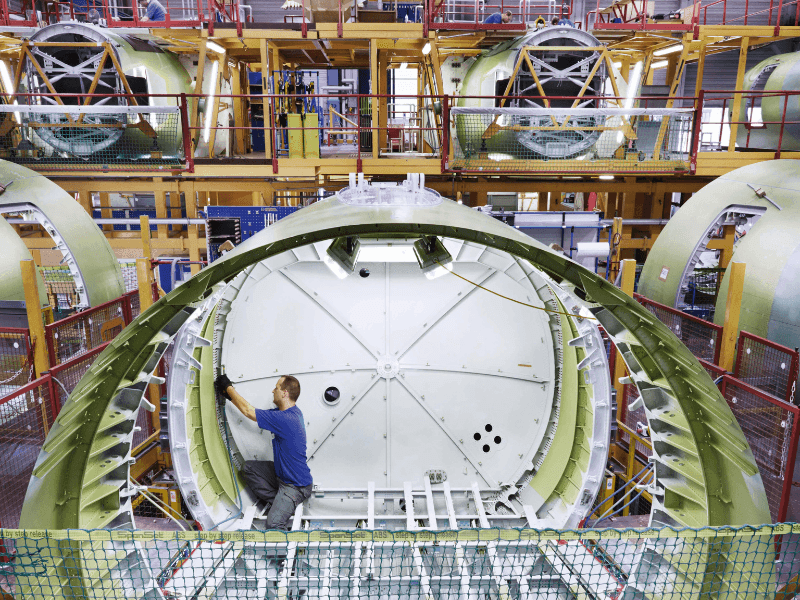

In collaboration with H&Z, Mubea Aerostructures reshaped its global supply chain in the aerospace sector. The result: better delivery performance, lower costs, and reduced supply risk – through targeted dual sourcing and strategic relocation.

- Home /

- Our Success Stories /

- Strengthening the Supply Chain through Dual Sourcing and Cost Reduction

Client Challenge

- Mubea Aerostructures faced critical structural challenges in its upstream supply chain:

- Delivery performance and quality from key suppliers were below expectations

- A high dependency on single-source suppliers across the entire direct spend volume posed significant supply risk

- There was no experience in making Make-or-Buy decisions, and potential for insourcing critical components remained untapped

- The company was caught in a “sandwich” position – pressured by price-sensitive clients and cost-driven suppliers

Margin expectations could not be met under the existing setup

To stay competitive, Mubea needed to rethink its sourcing model and improve resilience without compromising on quality.

H&Z Approach

H&Z took a strategic and hands-on approach to transform Mubea’s supply chain setup:

- Assessed the capabilities, capacities, technologies and cost structures of both internal and external suppliers

- Evaluated opportunities for Make-or-Buy, enabling an informed and fact-based shift toward dual sourcing

- Supported supplier scouting and development following the selection of suitable partners

- Facilitated the relocation and Transfer of Work (ToW) in close alignment with Airbus and across international operations

Developed a clear and transparent decision-making template to guide implementation

This approach not only addressed current bottlenecks but built a foundation for long-term supply chain stability.

Results

The collaboration led to tangible and sustainable improvements:

- Improved delivery performance, both in terms of on-time and in-spec deliveries

- Reduced cost of poor quality, with fewer delivery failures and quality issues

- Lower material costs, achieved through competitive dual sourcing and targeted supplier development

- Reduced supply risk, thanks to a diversified supplier base and clear Make-or-Buy logic

- Build-up of internal know-how, enabling better strategic sourcing decisions in the future

A scalable decision framework, supporting future relocations and sourcing initiatives

Mubea is now better positioned to navigate market dynamics with a more flexible, cost-effective and reliable supply chain.

Clemens Friedl, Managing Director at Mubea Aerostructures

“I can only say that working with you was a pleasure throughout. Your team was engaging and clear, understand their work down to the last detail and are a pleasant team to work with.”

About Mubea

Mubea Aerostructures is part of Mubea’s aviation division, with manufacturing locations in Oberpfaffenhofen (Germany) and Eger (Hungary). As a Tier-1 supplier for detailed parts in civil aircraft, the company plays a vital role in the aerospace supply chain. Its annual turnover exceeds €200 million.